Me ka holomua wikiwiki o ka ʻenehana, ua lilo nā huahana uila i ʻāpana koʻikoʻi o ke ola o kēlā me kēia lā o kānaka. ʻO nā ʻāpana, ma ke ʻano he "puʻuwai" o nā mea uila, he mea koʻikoʻi kēlā me kēia ʻanuʻu i kā lākou hana hana ʻana, a he kuleana koʻikoʻi ka pepa keleawe ma ka ʻoihana hana semiconductor. Me kona conductivity uila a me ka conductivity wela koʻikoʻi, he nui nā noi a me nā hana koʻikoʻi o ka pepa keleawe.

Kī i nā Ala Alakaʻi

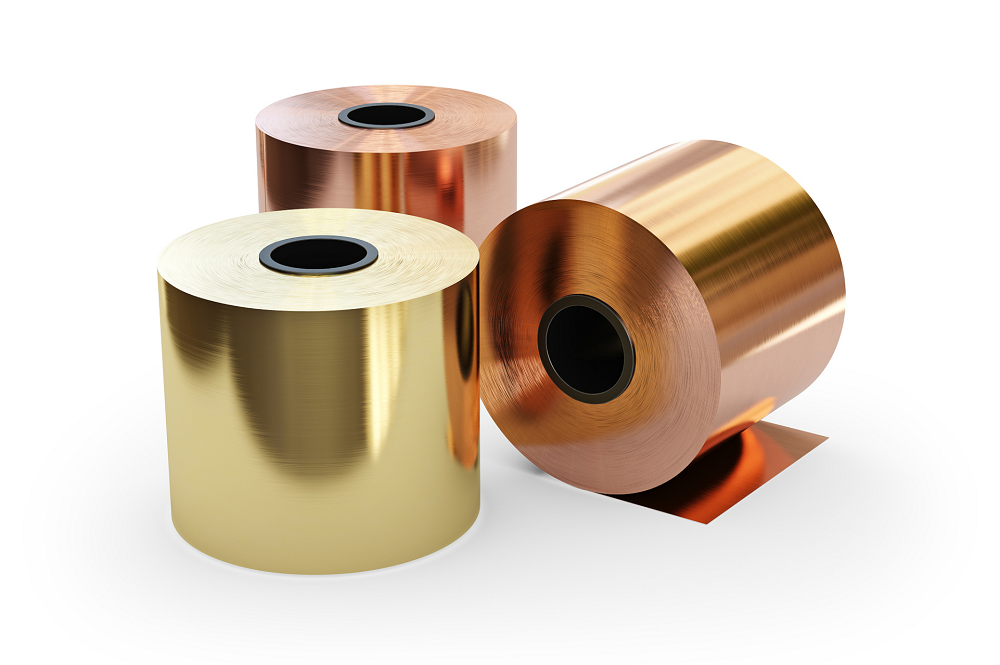

Pepa keleaweʻo ia kekahi o nā mea nui i hoʻohana ʻia i ka hana ʻana o nā papa kaapuni i paʻi ʻia (PCB), e lawelawe ana ma ke ʻano he kahua no ka hoʻopili ʻana i nā chips me nā ʻāpana uila ʻē aʻe. Ma kēia kaʻina hana, ua kālai ʻia ka pepa keleawe e hana i nā ala alakaʻi maikaʻi, e lawelawe ana ma ke ʻano he mau kahawai no ka hōʻailona a me ka hoʻoili mana. I ka hana semiconductor, inā he mau micro-connections i loko o ka chip a i ʻole nā pilina i ka honua waho, hana ka pepa keleawe ma ke ʻano he alahaka.

He Mea Kaua i ka Hoʻokele Wera

ʻAʻole hiki ke pale ʻia ka hana ʻana o ka wela i ka wā o ka hana ʻana o ka chip. Me kona conductivity thermal maikaʻi loa, he kuleana koʻikoʻi ka pepa keleawe i ka hoʻokele wela. Hoʻokele pono ia i ka wela i hana ʻia e ka chip, e hōʻemi ana i ke kaumaha wela o ka chip, a pēlā e pale ai iā ia mai ka pōʻino wela a hoʻolōʻihi i kona ola.

Kihi o ka hoʻopili ʻana a me ka pilina

He mea koʻikoʻi ka hoʻopili ʻana o ka hoʻohuihui kaapuni (IC) i ka hana ʻana i nā ʻāpana, apepa keleaweHoʻohana ʻia e hoʻohui i nā ʻāpana liʻiliʻi i loko o ka chip a hoʻokumu i nā pilina me ke ao waho. ʻAʻole pono wale kēia mau pilina i ka conductivity uila maikaʻi loa akā ʻo ka ikaika kino a me ka hilinaʻi kūpono hoʻi, nā koi e hoʻokō pono ai ka foil keleawe. Hōʻoiaʻiʻo ia e hiki i nā hōʻailona uila ke kahe manuahi a pololei i loko a ma waho o ka chip.

Mea i makemake ʻia no nā noi alapine kiʻekiʻe

I nā ʻenehana kamaʻilio alapine kiʻekiʻe e like me 5G a me ka 6G e hiki mai ana, he mea nui loa ka pepa keleawe ma muli o kona hiki ke mālama i ka conductivity maikaʻi loa ma nā alapine kiʻekiʻe. Hoʻokau nā hōʻailona alapine kiʻekiʻe i nā koi kiʻekiʻe ma ka conductivity a me ke kūpaʻa o nā mea, a ʻo ka hoʻohana ʻana i ka pepa keleawe e hōʻoiaʻiʻo i ka pono a me ke kūpaʻa o ka hoʻouna ʻana i nā hōʻailona, e lilo ia i mea pono ʻole i ka hana ʻana i nā chip alapine kiʻekiʻe.

Nā Pilikia a me ka Hoʻomohala ʻana i ka Wā E Hiki Mai Ana

ʻOiaipepa keleaweHe kuleana koʻikoʻi ko ia i ka hana ʻana i nā chips, ʻoiai ke neʻe nei ka ʻenehana chip i ka miniaturization a me ka hana kiʻekiʻe, ua kau ʻia nā koi kiʻekiʻe ma luna o ka maikaʻi a me ka ʻenehana hana o ka foil keleawe. ʻO ka mānoanoa, ka maʻemaʻe, ke kūlike, a me ke kūpaʻa o kāna hana ma lalo o nā kūlana koʻikoʻi he mau pilikia loea a nā mea hana e pono ai ke lanakila.

Ke nānā nei i mua, me ka hoʻomohala ʻana o nā mea hana a me nā kaʻina hana hou, e hoʻonui hou ʻia a hoʻonui ʻia ka noi a me ke kuleana o ka pepa keleawe i ka ʻoihana hana semiconductor. Inā paha e hoʻomaikaʻi ana i ka hana chip, e hoʻomaikaʻi ana i nā hoʻonā hoʻokele wela, a i ʻole e hoʻokō ana i nā koi o nā noi alapine kiʻekiʻe, e hoʻomau ka pepa keleawe i ka pāʻani i kahi kuleana nui, e kākoʻo ana i ka holomua mau a me ka hoʻomohala ʻana o ka ʻoihana hana semiconductor.

Ka manawa hoʻouna: Malaki-28-2024