Pepa keleaweHe haʻahaʻa ka nui o ka oxygen ma luna a hiki ke hoʻopili ʻia me nā ʻano substrates like ʻole, e like me ka metala, nā mea hoʻokaʻawale. A hoʻopili nui ʻia ka foil keleawe i ka pale electromagnetic a me ka antistatic. No ke kau ʻana i ka foil keleawe conductive ma luna o ka ʻili substrate a hui pū ʻia me ka substrate metala, e hāʻawi ia i ka hoʻomau maikaʻi loa a me ka pale electromagnetic. Hiki ke hoʻokaʻawale ʻia i: foil keleawe hoʻopili ponoʻī, foil keleawe ʻaoʻao hoʻokahi, foil keleawe ʻaoʻao pālua a me nā mea like.

Ma kēia paukū, inā ʻoe e aʻo hou aʻe e pili ana i ka pepa keleawe i ke kaʻina hana PCB, e ʻoluʻolu e nānā a heluhelu i ka ʻike ma lalo nei ma kēia paukū no ka ʻike ʻoihana hou aku.

He aha nā hiʻohiʻona o ka foil keleawe i ka hana ʻana o ka PCB?

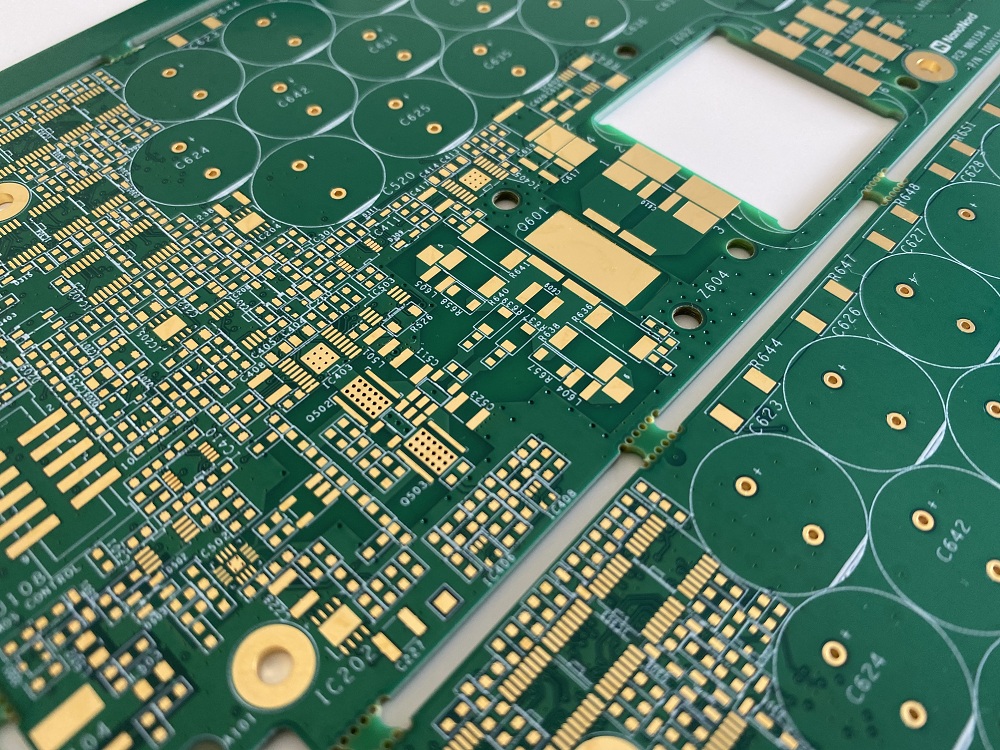

Pepa keleawe PCBʻo ia ka mānoanoa keleawe mua i hoʻopili ʻia ma nā papa o waho a me loko o kahi papa PCB multilayer. Ua wehewehe ʻia ke kaumaha keleawe ʻo ke kaumaha (ma nā auneke) o ke keleawe i loaʻa i hoʻokahi kapuaʻi kuea o ka ʻāpana. Hōʻike kēia palena i ka mānoanoa holoʻokoʻa o ke keleawe ma ka papa. Hoʻohana ʻo MADPCB i nā kaumaha keleawe ma lalo nei no ka hana ʻana o PCB (pre-plate). Nā kaumaha i ana ʻia ma oz/ft2. Hiki ke koho ʻia ke kaumaha keleawe kūpono e kūpono i ke koi hoʻolālā.

· I ka hana ʻana o ka PCB, aia nā pepa keleawe i loko o nā ʻōwili, he papa uila me ka maʻemaʻe o 99.7%, a me ka mānoanoa o 1/3oz/ft2 (12μm a i ʻole 0.47mil) - 2oz/ft2 (70μm a i ʻole 2.8mil).

· ʻOi aku ka haʻahaʻa o ka oxygen ma luna o ka pepa keleawe a hiki ke hoʻopili mua ʻia e nā mea hana laminate i nā mea kumu like ʻole, e like me ke kumu metala, polyimide, FR-4, PTFE a me ka keramika, e hana i nā laminates i uhi ʻia i ke keleawe.

· Hiki nō hoʻi ke hoʻokomo ʻia i loko o ka papa multilayer e like me ke kini keleawe ponoʻī ma mua o ke kaomi ʻana.

· I ka hana ʻana o ka PCB maʻamau, ʻo ka mānoanoa keleawe hope loa ma nā papa o loko e waiho mau ana ia o ka pepa keleawe mua; Ma nā papa o waho, hoʻopili mākou i ke keleawe 18-30μm keu ma nā ala i ka wā o ke kaʻina hana panel plating.

· ʻO ke keleawe no nā papa waho o nā papa multilayer ma ke ʻano o ka foil keleawe a paʻi pū ʻia me nā prepregs a i ʻole nā cores. No ka hoʻohana ʻana me nā microvias ma HDI PCB, aia pololei ka foil keleawe ma luna o RCC (keleawe i uhi ʻia me ka resin).

No ke aha e pono ai ka foil keleawe i ka hana ʻana o PCB?

ʻO ka pepa keleawe papa uila (ʻoi aku ka maʻemaʻe ma mua o 99.7%, mānoanoa 5um-105um) kekahi o nā mea kumu o ka ʻoihana uila. Ke ulu wikiwiki nei ka ʻoihana ʻike uila, ke ulu nei ka hoʻohana ʻana i ka pepa keleawe papa uila, ua hoʻohana nui ʻia nā huahana i nā helu helu ʻoihana, nā lako kamaʻilio, nā lako QA, nā pila lithium-ion, nā kīwī kīwila, nā mea hoʻopaʻa wikiō, nā mea pāʻani CD, nā mea kope, kelepona, ea hoʻoluʻu, nā mea uila kaʻa, a me nā consoles pāʻani.

Pepa keleawe ʻoihanaHiki ke hoʻokaʻawale ʻia i ʻelua mau māhele: ka pepa keleawe i ʻōwili ʻia (pepa keleawe RA) a me ka pepa keleawe kiko (pepa keleawe ED), kahi i loaʻa ai ka ductility maikaʻi o ka pepa keleawe kalena a me nā ʻano ʻē aʻe, ʻo ia ke kaʻina hana papa palupalu mua i hoʻohana ʻia ka pepa keleawe, ʻoiai ʻo ka pepa keleawe electrolytic he kumukūʻai haʻahaʻa o ka hana ʻana i ka pepa keleawe. Ma ke ʻano he mea nui ka pepa keleawe ʻōwili o ka papa palupalu, no laila he hopena koʻikoʻi nā ʻano o ka pepa keleawe kalena a me nā loli kumukūʻai ma ka ʻoihana papa palupalu.

He aha nā lula hoʻolālā kumu o ka pepa keleawe ma PCB?

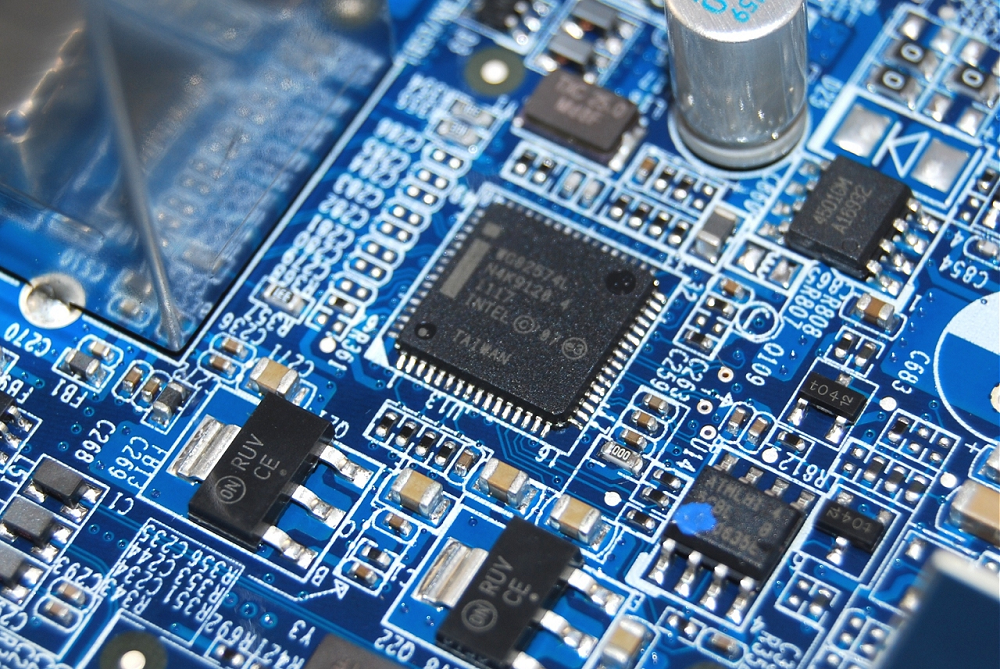

Ua ʻike anei ʻoe he mea maʻamau loa nā papa kaapuni paʻi i loko o ka hui o nā mea uila? Ke maopopo nei iaʻu aia kekahi i loko o ka mea uila āu e hoʻohana nei i kēia manawa. Eia nō naʻe, ʻo ka hoʻohana ʻana i kēia mau mea uila me ka ʻike ʻole i kā lākou ʻenehana a me ke ʻano hoʻolālā he hana maʻamau nō hoʻi. Ke hoʻohana nei ka poʻe i nā mea uila i kēlā me kēia hola akā ʻaʻole lākou i ʻike pehea lākou e hana ai. No laila eia kekahi mau ʻāpana nui o ka PCB i ʻōlelo ʻia e loaʻa kahi ʻike wikiwiki i ke ʻano o ka hana ʻana o nā papa kaapuni paʻi.

· He mau papa palaki maʻalahi ka papa kaapuni i paʻi ʻia me ka hoʻohui ʻana o ke aniani. Hoʻohana ʻia ka pepa keleawe no ke kahakiʻi ʻana i nā ala a hiki ke kahe o nā uku a me nā hōʻailona i loko o ka hāmeʻa. ʻO nā kaha keleawe ke ala e hāʻawi ai i ka mana i nā ʻāpana like ʻole o ka hāmeʻa uila. Ma kahi o nā uea, alakaʻi nā kaha keleawe i ke kahe o nā uku ma nā PCB.

· Hiki i nā PCB ke lilo i hoʻokahi papa a ʻelua papa hoʻi. ʻO hoʻokahi papa PCB nā mea maʻalahi. Loaʻa iā lākou ka foil keleawe ma kekahi ʻaoʻao a ʻo kekahi ʻaoʻao ka lumi no nā ʻāpana ʻē aʻe. ʻOiai ma ka PCB pālua-papa, ua mālama ʻia nā ʻaoʻao ʻelua no ka foil keleawe. ʻO nā papa pālua nā PCB paʻakikī me nā kaha paʻakikī no ke kahe ʻana o nā uku. ʻAʻohe foil keleawe e hiki ke hele kekahi i kekahi. Pono kēia mau PCB no nā mea uila kaumaha.

· Aia kekahi mau papa ʻelua o nā solders a me ka silkscreen ma ka PCB keleawe. Hoʻohana ʻia kahi solder mask e hoʻokaʻawale i ke kala o ka PCB. Nui nā kala o nā PCB i loaʻa e like me ka ʻōmaʻomaʻo, poni, ʻulaʻula, a pēlā aku. Hoʻākāka pū ka solder mask i ke keleawe mai nā metala ʻē aʻe e hoʻomaopopo i ka paʻakikī o ka pilina. ʻOiai ʻo ka silkscreen ka ʻāpana kikokikona o ka PCB, ua kākau ʻia nā leka a me nā helu like ʻole ma ka silkscreen no ka mea hoʻohana a me ka ʻenekinia.

Pehea e koho ai i ka mea kūpono no ka pepa keleawe ma ka PCB?

E like me ka mea i ʻōlelo ʻia ma mua, pono ʻoe e ʻike i ke ʻano hana no ka hoʻomaopopo ʻana i ke ʻano hana o ka papa kaapuni i paʻi ʻia. Loaʻa i nā hana o kēia mau papa nā papa like ʻole. E hoʻomaopopo kākou i kēia me ke kaʻina:

Mea substrate:

ʻO ke kahua kumu ma luna o ka papa plastik i hoʻokau ʻia me ke aniani ka substrate. ʻO ka substrate kahi ʻano dielectric o kahi pepa i hana pinepine ʻia me nā resins epoxy a me ka pepa aniani. Ua hoʻolālā ʻia kahi substrate i ke ʻano e hiki ai ke hoʻokō i ke koi e like me ka mahana hoʻololi (TG).

Lamination:

E like me ka maopopo mai ka inoa, ʻo ka lamination kekahi ala e loaʻa ai nā waiwai e pono ai e like me ka hoʻonui ʻana o ka thermal, ka ikaika shear, a me ka wela hoʻololi (TG). Hana ʻia ka lamination ma lalo o ke kaomi kiʻekiʻe. He kuleana koʻikoʻi ko ka lamination a me ka substrate i ke kahe ʻana o nā uku uila i loko o ka PCB.

Ka manawa hoʻouna: Iune-02-2022