Me ke kāhea nui ʻia i loko o nā ʻano huahana ʻoihana like ʻole, ua manaʻo ʻia ke keleawe he mea maʻalahi loa.

Hana ʻia nā pepa keleawe e nā kaʻina hana hana kikoʻī loa i loko o ka wili pepa alumini e komo pū ana me ka ʻōwili wela a me ke anu.

Me ka alumini, hoʻohana nui ʻia ke keleawe i nā huahana ʻoihana ma ke ʻano he mea maʻalahi loa i waena o nā mea metala ʻole-ferrous. I nā makahiki i hala iho nei, ua piʻi nui ke koi no ka pepa keleawe no nā huahana uila e like me nā kelepona paʻalima, nā kāmela kikohoʻe, a me nā polokalamu IT.

Hana ʻana i ka pepa kini

Hana ʻia nā pepa keleawe lahilahi ma o ka electrodeposition a i ʻole ka ʻōwili ʻana. No ka electrodeposition, pono e hoʻoheheʻe ʻia ke keleawe kiʻekiʻe i loko o kahi waikawa e hana i kahi electrolyte keleawe. Hoʻopili ʻia kēia hopena electrolyte i loko o nā pahu i hoʻokomo hapa ʻia, e wili ana i hoʻouka ʻia me ka uila. Ma luna o kēia mau pahu ua electrodeposited ʻia kahi ʻili lahilahi o ke keleawe. Ua kapa ʻia kēia kaʻina hana ʻo plating.

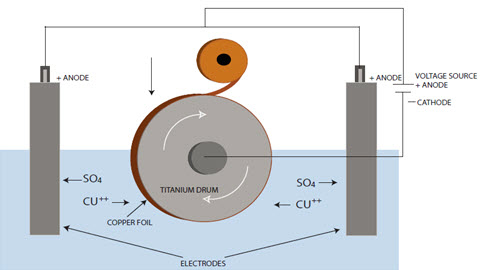

Ma ke kaʻina hana hana keleawe i hoʻopili ʻia i ka electrodeposited, ua waiho ʻia ka pepa keleawe ma luna o kahi pahu wili titanium mai kahi hopena keleawe kahi i hoʻopili ʻia ai i kahi kumu uila DC. Hoʻopili ʻia ka cathode i ka pahu a ua hoʻoluʻu ʻia ka anode i loko o ka hopena electrolyte keleawe. Ke hoʻopili ʻia kahi kahua uila, ua waiho ʻia ke keleawe ma luna o ka pahu i kona wili ʻana ma kahi wikiwiki loa. He laumania ka ʻili keleawe ma ka ʻaoʻao pahu ʻoiai he ʻino ka ʻaoʻao ʻē aʻe. ʻO ka lohi o ka wikiwiki o ka pahu, ʻoi aku ka mānoanoa o ke keleawe a me ka hope. Hoʻowalewale ʻia ke keleawe a hōʻiliʻili ʻia ma luna o ka ʻili cathode o ka pahu titanium. Hele ka ʻaoʻao matte a me ka pahu o ka pepa keleawe i nā pōʻaiapuni lapaʻau like ʻole i hiki ai i ke keleawe ke kūpono no ka hana PCB. Hoʻonui nā lāʻau lapaʻau i ka hoʻopili ʻana ma waena o ke keleawe a me ka dielectric interlayer i ka wā o ke kaʻina hana lamination i uhi ʻia i ke keleawe. ʻO kekahi pono o nā lāʻau lapaʻau, ʻo ia ka hana ʻana ma ke ʻano he mau mea anti-tarnish ma ka hoʻolohi ʻana i ka oxidation o ke keleawe.

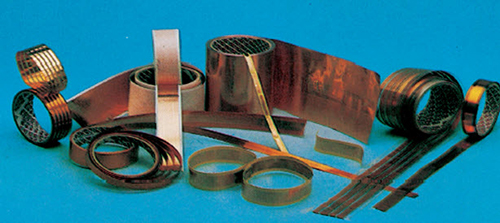

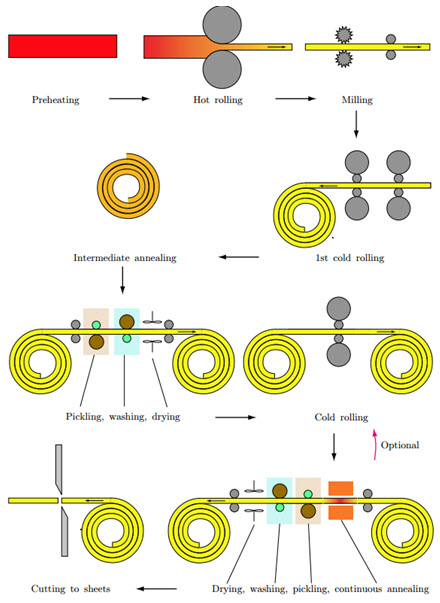

Kiʻi 1:Ke Kaʻina Hana Keleawe i Hoʻopaʻa ʻia ma ke ʻAno Uila Hōʻike ke Kiʻi 2 i nā kaʻina hana hana o nā huahana keleawe i ʻōwili ʻia. Ua māhele ʻia nā lako ʻōwili i ʻekolu ʻano; ʻo ia hoʻi, nā wili ʻōwili wela, nā wili ʻōwili anu, a me nā wili foil.

Hoʻokumu ʻia nā wili o nā foil lahilahi a hana ʻia ka mālama kemika a me ka mīkini a hiki i ka wā e hoʻokumu ʻia ai i ko lākou ʻano hope loa. Hāʻawi ʻia kahi ʻike kikoʻī o ke kaʻina hana ʻōwili o nā foil keleawe ma ke Kiʻi 2. Hoʻomehana ʻia kahi poloka keleawe i hoʻolei ʻia (nā ana kokoke: 5mx1mx130mm) a hiki i 750°C. A laila, ʻōwili wela ʻia a hoʻohuli ʻia i kekahi mau ʻanuʻu i lalo a hiki i ka 1/10 o kona mānoanoa mua. Ma mua o ka ʻōwili anu mua ʻana, lawe ʻia nā unahi i hoʻomaka mai ka mālama wela ʻana e ka wili ʻana. I ke kaʻina hana ʻōwili anu, ua hoʻemi ʻia ka mānoanoa i kahi 4 mm a ua hoʻokumu ʻia nā pepa i mau wili. Hoʻomalu ʻia ke kaʻina hana i ke ʻano e lōʻihi ai ka mea a ʻaʻole e hoʻololi i kona laulā. ʻOiai ʻaʻole hiki ke hana hou ʻia nā pepa i kēia mokuʻāina (ua paʻakikī nui ka mea hana) hana lākou i kahi mālama wela a hoʻomehana ʻia i kahi 550°C.

Ka manawa hoʻouna: ʻAukake-13-2021